Lagerverwaltungssystem LTWMS

Steigerte Transportleistung durch KI‑gestützte Lagerverwaltungslösungen

LogoTek Lagerverwaltungssysteme LTWMS eignen sich für das Materialmanagement in verschiedenen Branchen, mit besonderem Fokus auf Schwerindustrie und Metallverarbeitung.

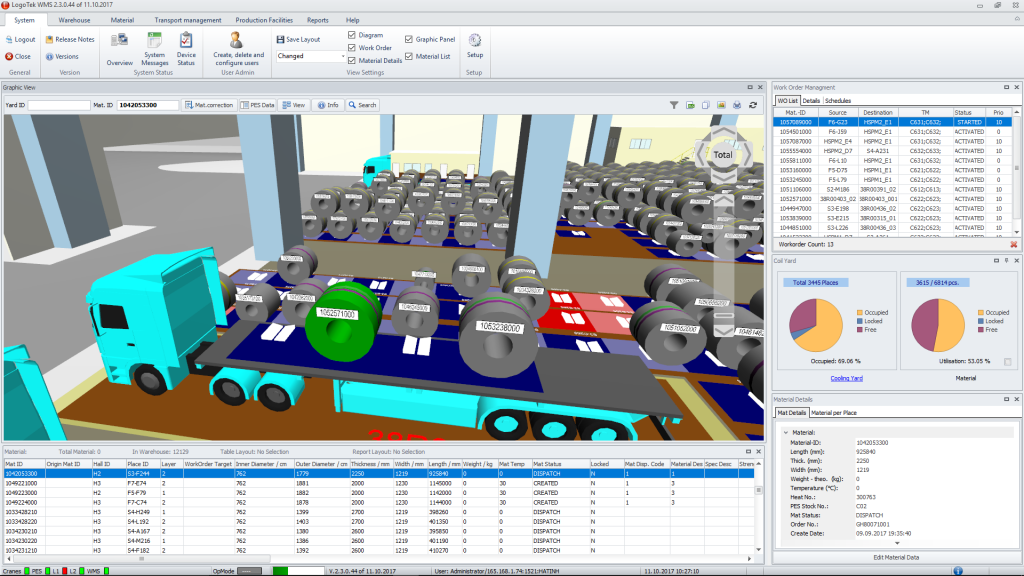

Der Anwender erhält durch das Lagerverwaltungssystem Daten über Materialbewegungen, die Belegung des Lagerplatzes und den Betriebsstatus der Krane. Arbeitsaufträge für Krane und andere Transportmittel werden auf Basis von Produktionsplanungsdaten generiert. Statistische Informationen zum Lagerstatus sind verfügbar. Ein Krankoordinatensystem (KKS) zur Transportüberwachung oder vollständig automatisierte Krane können in das LVS integriert werden. In diesem Fall wird das Lagerabbild anhand der von den Kranen gelieferten Prozessdaten aktualisiert. Die Auswahl der für die Einlagerung verwendeten Lagerplätze erfolgt auf Grundlage von Optimierungsregeln und Restriktionen.

Eigenschaften des LTWMS

Vorteile des LTWMS

Der LTWMS‑Server betreibt die Datenbank und die WMS‑Prozesse für verschiedene Aufgaben.

Unterstützt werden Oracle‑ oder Microsoft SQL‑Server‑Datenbanken.

Zu den WMS‑Prozessen gehören:

WMS integriert eine Fahrzeug‑Client‑Software, die für den Einsatz auf Fahrzeugen wie Hallenkranen, Gabelstaplern oder Schwerlastträgern optimiert ist.

Der Fahrzeug‑Client unterstützt unterschiedliche 2D‑ und 3D‑Ansichten, abhängig von Fahrzeug‑ und Materialtyp. Verschiedene Arten von Positionierungssystemen werden unterstützt, und die Parametrierung sowie Überwachung der Fahrzeugsensoren kann mit dieser Software durchgeführt werden.

LTWMS unterstützt mobile Client‑Geräte unterschiedlicher Art.

Webbasierte Anwendungen für Mobiltelefone, industrielle PDAs und Tablet‑Computer stehen zur Verfügung. Die Anwendungssoftware ist für den Einsatz in Umgebungen mit schwieriger Konnektivität bzw. instabilen Netzwerken optimiert.

Verschiedene Identifikationstechnologien wie Barcode, RFID und 2D‑Codes werden unterstützt.

Arbeitsaufträge werden vom WMS automatisch auf Basis von Lagerregeln und Restriktionen erstellt.

Produktionspläne, Materialeigenschaften und Kranstatus werden genutzt, um Arbeitsaufträge zu generieren und ein geeignetes Transportmittel auszuwählen. KI‑basierte Algorithmen unterstützen die Auswahl eines passenden Lagerplatzes. Lagerregeln können im WMS bearbeitet werden.

Temperaturmodelle stehen zur Verfügung, um die aktuelle Materialtemperatur zu berechnen und diese bei der Auswahl geeigneter Materialien für das Beladen oder die Weiterverarbeitung zu berücksichtigen.

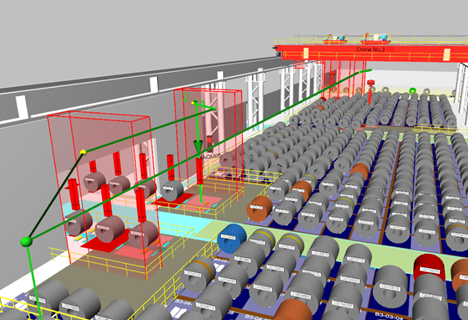

LTWMS integriert vollautomatische Krane.

Es stellt Routing‑Funktionen bereit, um Hindernisse zu umfahren, Kollisionen zu vermeiden und Krandaten zu Wartungszwecken zu erfassen.