Industrial Automation

Transforming Industrial Performance with Advanced Control

Industrial automation is a key enabler for achieving consistent process stability, high equipment availability, and optimized throughput in the steel and heavy industries. Automated control architectures—ranging from PLC- and DCS-based systems to edge and SCADA platforms—ensure precise coordination of complex, interdependent processes such as melting, casting, rolling, and thermal treatment.

Robust sensor technology, real-time data acquisition, and advanced diagnostics support continuous condition monitoring and predictive maintenance, reducing unplanned downtime in critical production areas. Integrated drive and motion-control solutions enable accurate material handling and positioning, even under extreme temperatures, heavy loads, and mechanical stress.

By standardizing interfaces, enhancing data transparency, and improving response times, industrial automation systems increase process reliability, energy efficiency, and product quality. This allows steel plants and heavy-industry facilities to operate more safely, maintain stable production windows, and extend the lifecycle of equipment in highly demanding environments.

Here are some project examples:

Our developers are familiar with Siemens S7 PLC systems of the 1200,1500, 300 and 400 families. For smaller automation systems we use Codesys.

Synchronized drive technology with advanced tension control delivers maximum precision and stability in the processing of continuous materials such as steel coils, paper rolls, and plastic films. By coordinating multiple drive axes in real time, the system maintains perfect tension across the entire line—ensuring smooth unwinding, accurate positioning, and consistent product quality even at high speeds. Intelligent algorithms automatically compensate load changes, varying material properties, and dynamic process conditions. Whether in steel processing, paper production, or film manufacturing, our solutions provide the reliability and performance needed for efficient, high-quality continuous material handling.

Low-voltage switchgear ensures safe, reliable, and efficient power distribution throughout your plant. With modern protection technology, modular designs, and intelligent communication interfaces, our switchgear solutions deliver maximum uptime and seamless integration into your automation and energy systems. Designed for demanding industrial environments, they provide robust protection, easy maintenance, and the flexibility needed to scale your operations with confidence.

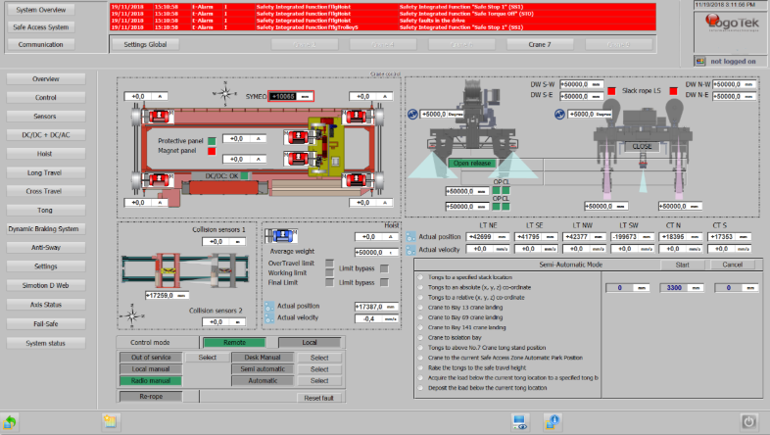

Our WinCC-based client/server HMI systems provide a scalable and highly reliable platform for plant-wide visualization and control. With centralized data management and fully integrated redundancy options, the system ensures continuous availability and consistent real-time information across all operator stations. Advanced communication, secure user management, and powerful diagnostics enable safe, efficient operation in demanding industrial environments. Designed for flexibility and seamless integration, WinCC delivers the performance and transparency needed for high-availability automation systems.

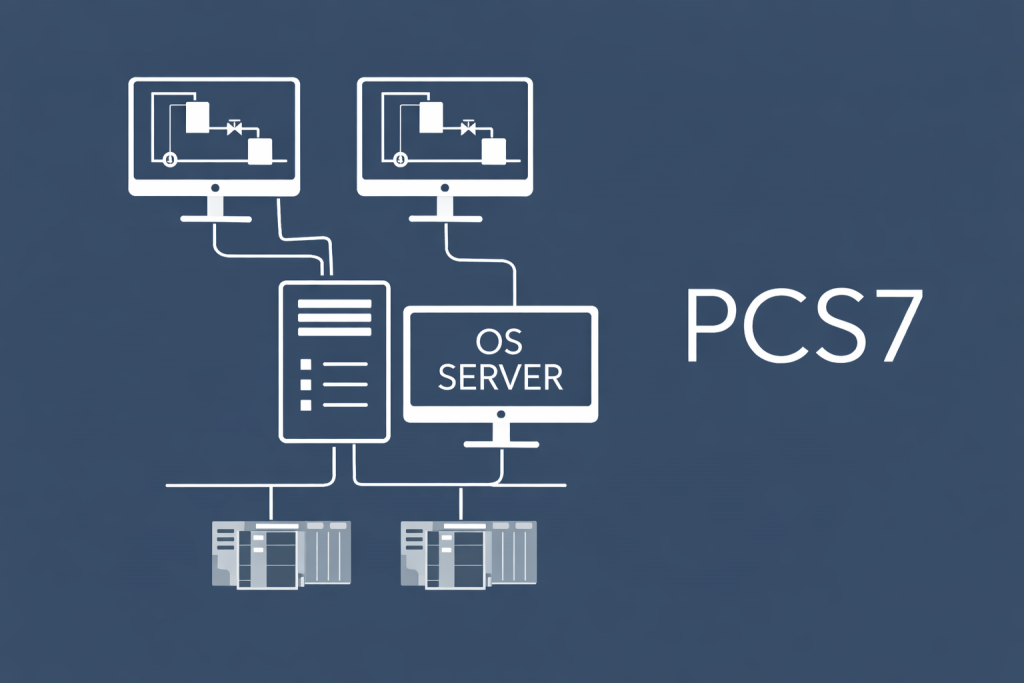

With PCS 7, we implement reliable and scalable process control solutions for demanding industrial environments. Our teams design and commission complete PCS-7 architectures—including redundant controllers, flexible I/O structures, and integrated safety—ensuring high availability and stable operation.

We deliver turnkey solutions that connect drives, field devices, HMI systems, and MES/ERP interfaces into one seamless automation platform. With project experience in steel, heavy industry, energy, and material handling, we help customers modernize plants, improve process quality, and achieve efficient, future-proof automation.

We modernize drive systems, change from DC to AC drives etc.