Warehouse Management System LTWMS

Increased transport performance by AI driven warehouse management solutions

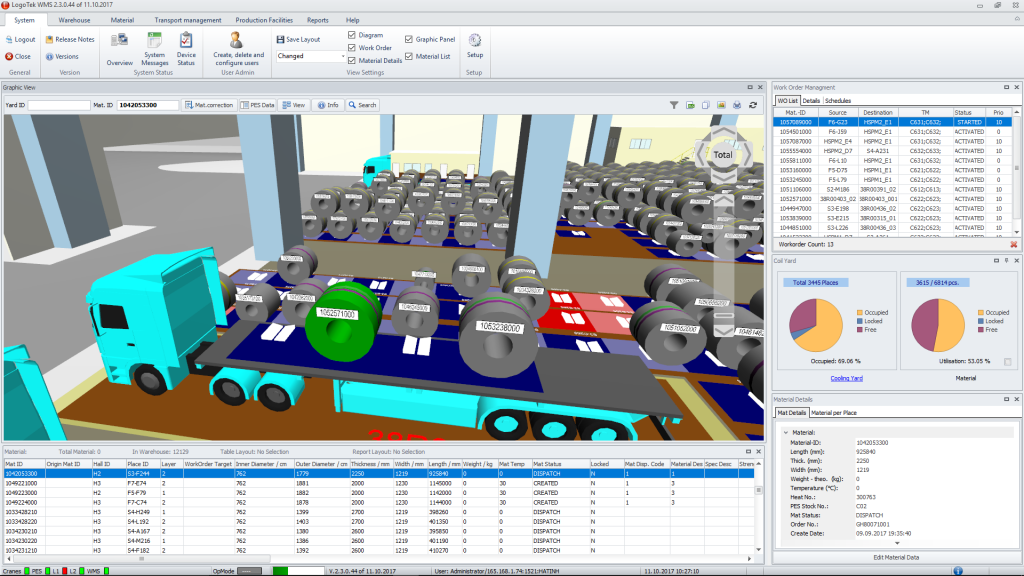

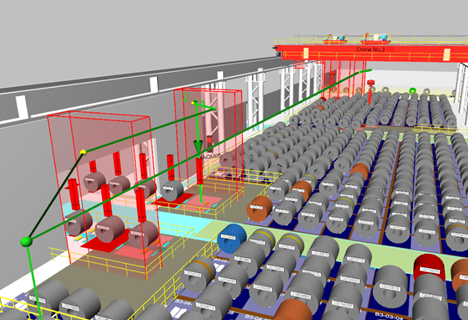

LogoTek warehouse management systems LTWMS are suitable for the material management in different industries, with special focus on heavy industries/metal. The operator can get data about material movements, storage yard occupation and crane operational status. Work orders for cranes and other means of transportation are generated on basis of production planning data. Statistical information of storage yard status is available. A crane tracking system for transport monitoring, or a complete automation system can be integrated into the WMS. In this case the storage yard image is updated on basis of process data received from the cranes. The selection of storage yard locations is performed on basis of optimization rules and restrictions.

Key features of LTWMS

The LTWMS-Server is running the database and WMS processes for verious tasks. Oracle or Microsoft SQL-Server databases are supported. WMS processes include

The WMS Client is a powerful user interface for the operation of the warehouse. It combines a sophisticated 3D and 2D real time visualization with a comprehensive set of functions for

WMS integrates a vehicle client software that is optimized for use at vehicles like overhead cranes, fork lifts or heavy load carriers. The vehicle client supports different 2D and 3D views depending on vehicle and material type. Different types of positioning systems are supported, and parameterization and monitoring of the vehicle sensors can be performed with this software.

LTWMS supports mobile client devices of different types. Web based applications for mobile phones, industrial PDA, tablet computers are available. The application software is optimized to be used in environments with difficult connectivity/unstable networks.

Various identification technologies like barcode, RFID and 2D codes are supported.

A warehouse management system needs to be connected to various production facilities and Level 1..3 systems of the steel plant. Interfaces can be configured individually for each application area. Examples are:

Work order are created automatically by the WMS based on storage rules and restrictions. Production schedules, material properties and crane status are used to create work orders and select a means of transport for the transport. AI based algorithms help to find a suitable storage location. Storage rules can be edited in the WMS.

Temperature models are available to calculate the actual material temperature and consider this for the selection of suitable material for loading or further processing.

Real time update of the material location requires modern sensor technology. LTWMS integrates sensors for various kinds of transport equipment, like cranes, fork lifts, roller tables. Used techologies are

LTWMS integrates fully automatic cranes. It provides routing functions to circumnavigate obstacles, avoid collision and records crane data for maintenance purposes.