Crane Technology

Enhanced Productivity through Crane Upgrade and Automation

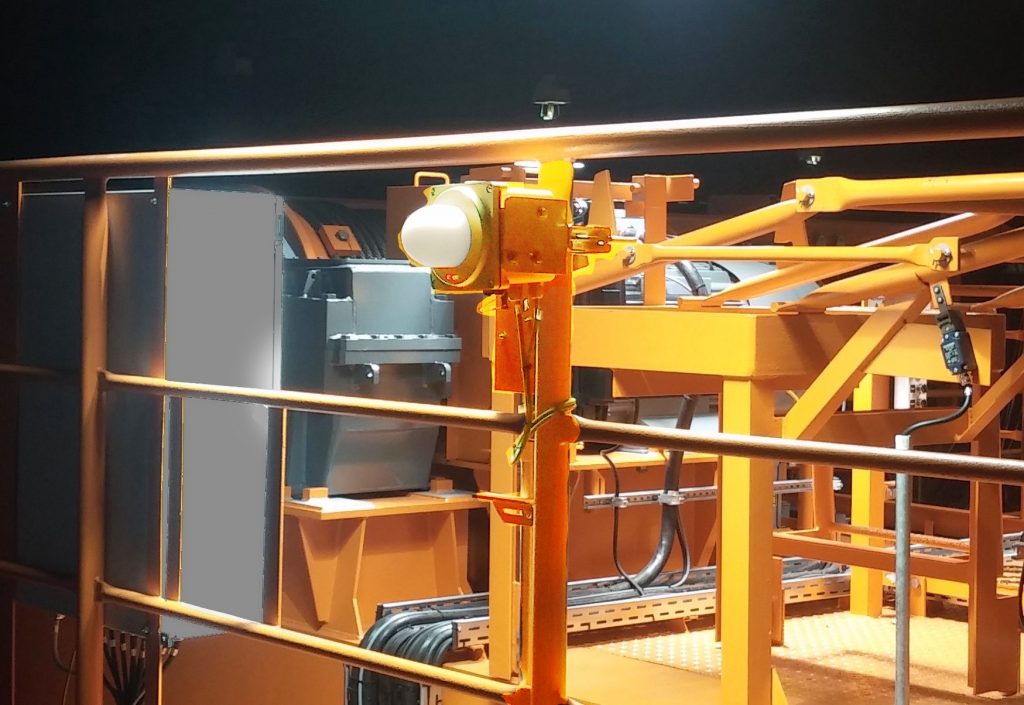

For more than 20 years, we have been a trusted supplier of automation components, drives, and sensor technologies for both crane modernizations and new crane projects. Our dedicated solutions enable fully manless operation and are engineered for environments where reliability and safety cannot be compromised. Our technology is deployed worldwide in industries such as

LogoTek supports all phases of your project – from basic and detailed engineering to hardware and software delivery, commissioning, training, and comprehensive after-sales service.

Design, supply and commissioning of drive systems for manually and automatic operated cranes. Special focus on Siemens frequency inverter technology. Service includes:

There are still tens of thousands of cranes with DC drives in operation worldwide. Even though many of these cranes are decades old, their mechanical structure is often still robust, and upgrading them to modern drive technology can significantly improve performance at a reasonable cost. LogoTek provides modernization concepts with high-power DC/DC converters that allow the existing power infrastructure to be used to supply modern asynchronous drives.

Fully automatic cranes can increase operational performance significantly. We provide solutions for automatic operation of new cranes, or retrofit/modernization of existing cranes. This includes:

Increased automation levels require modern sensor technology. We supply sesnors for various kinds of transport equipment, like cranes, fork lifts, roller tables. Used techologies are

We supply collision-avoidance systems based on radar and optical systems. In addition to safety-rated collision avoidance software based solutions are used to keep cranes at safe distance before the hardware sensors are activated.

Our heavy-duty weighing and load-sensing solutions are based on load pins, load cells, and optical or mechanical sensors. They can be used for:

Predictive maintenance helps companies increase equipment availability, reduce unplanned downtime, and extend the lifetime of critical components. By continuously monitoring key parameters and using data analytics to detect early signs of wear or failure, maintenance can be scheduled exactly when needed. This minimizes repair costs, prevents costly breakdowns, and improves overall operational efficiency. In addition, predictive maintenance enhances safety and supports better planning of spare parts and resources.

An anti-sway system transforms crane operations by ensuring fast, precise, and stable load handling. By automatically reducing load swing, operators can move goods more quickly and safely, even in challenging environments. This not only boosts productivity but also minimizes the risk of accidents, equipment damage, and costly downtime. With smoother movements and consistent control, anti-sway technology increases throughput, improves positioning accuracy, and enhances overall workplace safety—delivering measurable performance gains from day one.

Nowadays, remote operation of cranes is a convenient and resource-saving alternative to traditional cabin control. When combined with semi-automatic or fully automatic modes, a single operator can manage several cranes efficiently. Our remote-control solutions incorporate:

This setup improves operator comfort, enhances productivity, and ensures safe and reliable crane operation from a centralized control room.